kitchen fire suppression systems

PRODUCTS

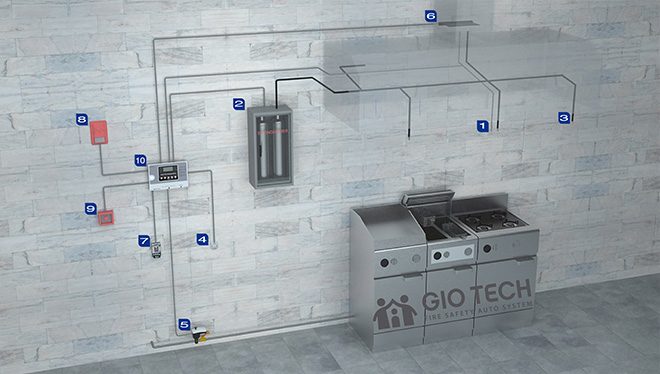

Kitchen Fire Suppression Systems.

- May be used in conjunction with other devices with additional external sirens, manual switches, and contact signals.

- Temperature adjustment (scope of configuration between 20℃ ~ 250℃) depending on commercial kitchen environment.

- 1st and 2nd stage warning system based on temperature sensing.

- During the 1st stage warning, the gas valve, damper, andturned off the electricity

- During the 2nd stage warning, the automatic fire suppression system is activated simultaneously - The control panel enables easy maintenance and repairs with its self-diagnostic features

- Use of the extinguishing agent that is optimized and enhanced for class K fires.

- When the fire extinguishing agent is released, it protects the environment by not leaving behind a residue.

Components of Kitchen Fire Suppression Systems

| NO | Description | Number that can be installed |

|---|---|---|

| 1 | Temperature sensor | 2 |

| 2 | Fire Extinguisher | 2 |

| 3 | Nozzle | 5 |

| 4 | Gas detector | 1 |

| 5 | Gas shutoff device | 1 |

| 6 | Damper | 1 |

| 7 | Magnetic Contactor | 1 |

| 8 | Siren | 1 |

| 9 | Manual Switch | 1 |

| 10 | Control Panel | 1 |

Control panel: GS 101

| Division | Specification |

|---|---|

| Working Voltage | 100 ~ 240V AC |

| Frequency Range | 50 ~ 60Hz |

| Power Consumption | 6W(normal) |

| Operating Temperature | -20℃ ~ 40℃ |

| Size(mm) | 275(W) x 215(H) x 77(D) |

| Weight(kg) | 2.2 |

Temperature Sensor: TS 033

| Division | Specification | ||

|---|---|---|---|

| Type | Temperature sensor type(Thermistor type) | ||

| LEVELⅠ (1st) | Operation temperature (Default) |

Temperature 1(Hood) 80℃ (176℉) |

Temperature 2(Duct) 150℃ (302℉) |

| Operating Range | 50℃ ~ 250℃ | ||

| LEVEL Ⅱ (2nd) | Operation temperature (Default) |

Temperature 1(Hood) 100℃ (212℉) |

Temperature 2(Duct) 200℃ (392℉) |

| Operating Range | 50℃ ~ 250℃ | ||

Fire Extinguisher: FE 036

| Division | Specification |

|---|---|

| Chemical formula | K2CO3 |

| Capacity / Charge | 5.1ℓ / 3.6ℓ |

| Material / Thickness | STS 304 / 1.2t |

| Charging Pressure | 9.8kg/cm2 |

| Operating Temperature | -20℃ ~ 40℃ |

| Ejection Time | Within 60 seconds |

| Size(mm) | Φ140X455 |

| Charged Weight(kg) | 7.12 |

Discharge Nozzle: DN 045(065)

| Division | Specification |

|---|---|

| Ejection Angle | 45°, 65° |

| Available Height of Installation | 1m ~ 1.3m |

| Spraying Area | 600mm ~ 700mm |

| Material | Copper Alloy / Chrome - coated |

| Size(mm) | Φ21X74 / Φ16X45 |

| Weight(g) | 120 / 60 |

Gas Detector: GD 100(101)

| Division | Specification |

|---|---|

| Working Voltage | 12V DC |

| Sensing | Catalytic Combustion Type |

| Detectable Gases | LPG, LNG |

| Sensing Density | Less than 1/4 of the Lower- Explosive-Limit(LEL) LPG(0.45%), LNG(1.25%) |

| Working Currency | 110mA |

| Operating Temperature | -20℃ ~ 40℃ |

| Size(mm) | 70(W) x 96(H) x 35(D) |

| Weight(g) | 80 |

Gas Shutoff Device: SD 020

| Division | Specification | |

|---|---|---|

| Working Voltage | 12V DC | |

| Pipe Size | mm | 15, 20, 25 |

| inch | 1/2”, 3/4”, 1” | |

| Shut-off Speed | Within 12 seconds | |

| Shut-off Torque | More than 5.9(Nㆍm) | |

| Durability | More than 6,000times | |

| Operating Temperature | -20℃ ~ 40℃ | |

| Size(mm) | 111(W) x 165(H) x 75(D) | |

| Weight(kg) | 0.68 | |

● You can take a pick of a gas shut-off device for 15A(1/2B), 20A(3/4B), 25A(1B).

Damper: FD 024

| Division | Specification |

|---|---|

| Working Voltage | 24V DC |

| Power Consumption | 80mA(minimum) ±10% 500mA(maximum) ±10% |

| Shut-off Speed | Within 25 seconds |

| Working Angle | 0 ~ 90゜±5゜ |

| Operating Wind Speed | Less than 15m/sec |

| Size(mm) | 85(W) x 160(H) x 73(D) |

| Weight(kg) | 0.78 |

| *For option | |

Magnetic Contactor: MC 018

| Division | Specification |

|---|---|

| Frame Size | 22AF |

| Number of poles | 3 pole |

| Rated current | 18A |

| Rated insulation voltage | 690V |

| *For option | |

Siren: FS 024

| Division | Specification |

|---|---|

| Working Voltage | 24V DC |

| Alarm Sound | 90 ~ 100dB |

| Flash Intensity | About 1.2WS |

| Flash Period | About 1.5S |

| Size(mm) | 130(W) x 125(H) x 48(D) |

| Weight(g) | 140 |

| *For option | |

Manual Switch: MS 100

| Division | Specification |

|---|---|

| Driving Method | Contact point method |

| Operating Temperature | -20℃ ~ 40℃ |

| Size(mm) | 88(W) x 52(H) x 88(D) |

| Weight(g) | 170 |

| *For option | |

● The specifications or form of the product pictured above may change.